What is the difference between mold injection processing and blow molding processing

1. The process of injection molding and blow molding is different.

Blow molding is injection + blowing; injection molding is injection +

pressing; blow molding must have the head left by the blowpipe, and

injection molding must have Gate section.

2. Generally speaking, injection molding is a solid core body, blow

molding is a hollow core body, and the blow molding surface is uneven.

Blow molding has a blowing port.

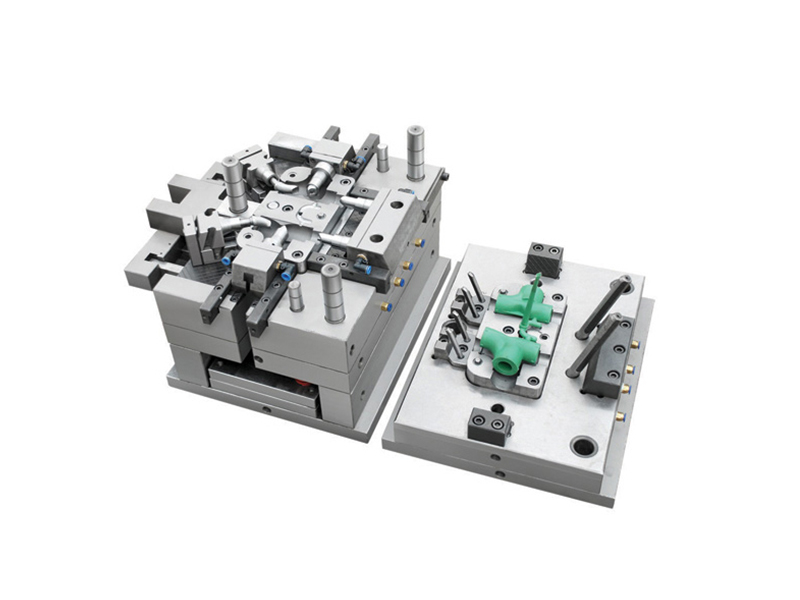

3. Injection molding process, that is, thermoplastic injection molding.

This method is to melt the plastic material and then inject it into the

film cavity. Once the molten plastic enters the mold, it is cooled and

shaped into a certain shape according to the mold cavity. The resulting

shape is often the final product, and no other processing is required

before equipment or use as a final product. Many details, such as

protrusions, ribs, and threads, can be formed in one step of injection

molding. The injection molding machine has two basic components:

injection equipment and clamping equipment for melting and feeding

plastic into the mold. The effect of the model equipment is:

1) Make the mold close under the condition of receiving the injection pressure;

2) Take the product out of the injection device to melt the plastic

before it is injected into the mold, and then control the pressure and

speed to inject the melt into the mold. The injection equipment

currently used has two plans: screw preplasticizer or two-stage

equipment, and reciprocating screw. The screw pre-plasticizer uses a

pre-plasticizing screw (the first level) and then injects the molten

plastic into the injection rod (the second level). The benefits of the

screw preplasticizer are stable melt quality, high pressure and high

speed, and precise injection volume control (using mechanical thrust

devices at both ends of the piston stroke).

Blow molding: also known as hollow blow molding, blow molding

processing, a rapidly developing plastic processing method. The tubular

plastic parison obtained by extrusion or injection molding of the

thermoplastic resin is placed in a split mold while it is hot (or heated

to a softened condition). After the mold is closed, compressed air is

injected into the parison to blow the plastic parison It expands and

clings to the inner wall of the mold, and after cooling and demolding,

various hollow products are obtained. The production process of blown

film is very similar in principle to blow molding of hollow products,

but it does not use molds. From the perspective of plastic processing

technology classification, the molding process of blown film is usually

included in the extrusion. The blow molding process was used to produce

low-density polyethylene vials during the Second World War.